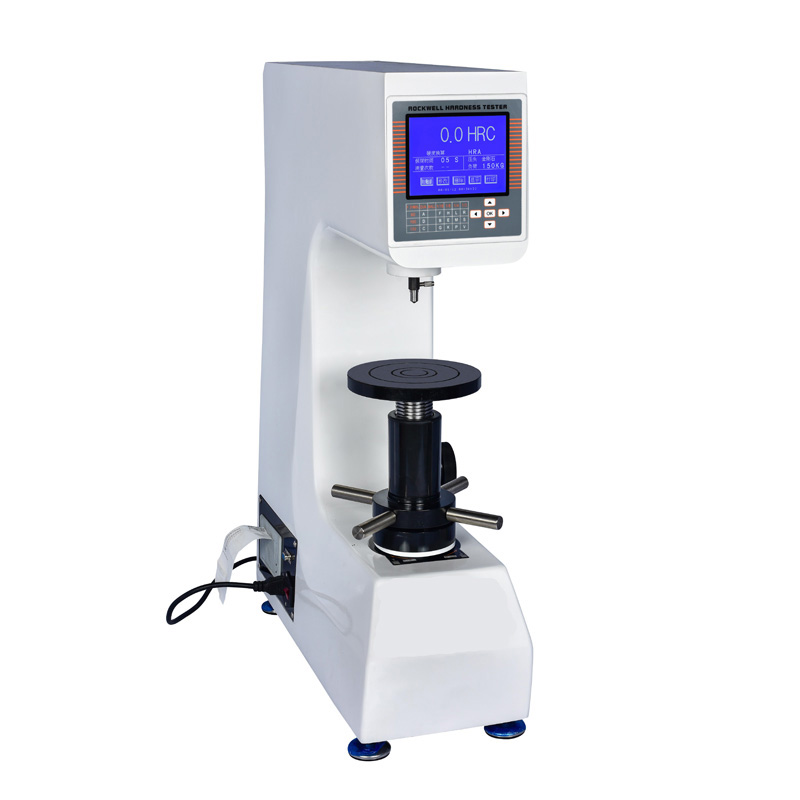

HRTS-150 Touch Screen Digital Rockwell Hardness Tester

NO:Touch Screen Digital Rockwell Hardness TesterWe"re here to help:

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

1. Simple Introduction

HRTS-150 Touch Screen digital display Rockwell hardness tester is a new generation of high-performance, high-precision and stable high-performance products. Its appearance is novel, the shell is cast in one piece, the stability is high, and its touch screen interface is menu-oriented. The operation is simple, intuitive and convenient. The measuring device adopts grating sensor and computer control, and the hardness indication value is directly displayed on the liquid crystal screen. It is a mechanical and electrical integration hardness testing instrument. It can automatically convert various hardness parameters to each other to identify the minimum thickness of the test piece. When the cylinder is tested, the correction amount is automatically added. Built-in printer to read the relevant test results. Automated operation eliminates human error and reading errors! At the same time, the machine is also equipped with an emergency stop device, which is safer to use.

Main function and features:

1. Directly display the test hardness value, conversion value, maximum value, minimum value, average value, etc. through a 5.6-inch LCD touch screen;

2, through the built-in system, electronic debugging hardness value error, adjustment range: 95% -105%.

3. The shell is formed by special sand-casting process. The structure is stable and not deformed, and it can work under harsh environment. The car paint has high grade and strong scratch resistance. It is still bright and new for many years.

4. When the cylinder is tested, the correction amount can be added automatically.

5. We have the ability to develop and design, manufacture and process our own machines, and provide replacement and maintenance upgrade services for the life of the machine;

Main use and the scope of application:

Cast and forged parts · Sample testing and acceptance testing

Planar and cylindrical workpieces ·Steel, non-ferrous metals

Automotive and aerospace industry ·Carbide, ceramic, stainless steel

Laboratory and workshop

2. Main technical parameter:

HRTS-150 Touch Screen digital display Rockwell hardness tester is a new generation of high-performance, high-precision and stable high-performance products. Its appearance is novel, the shell is cast in one piece, the stability is high, and its touch screen interface is menu-oriented. The operation is simple, intuitive and convenient. The measuring device adopts grating sensor and computer control, and the hardness indication value is directly displayed on the liquid crystal screen. It is a mechanical and electrical integration hardness testing instrument. It can automatically convert various hardness parameters to each other to identify the minimum thickness of the test piece. When the cylinder is tested, the correction amount is automatically added. Built-in printer to read the relevant test results. Automated operation eliminates human error and reading errors! At the same time, the machine is also equipped with an emergency stop device, which is safer to use.

Main function and features:

1. Directly display the test hardness value, conversion value, maximum value, minimum value, average value, etc. through a 5.6-inch LCD touch screen;

2, through the built-in system, electronic debugging hardness value error, adjustment range: 95% -105%.

3. The shell is formed by special sand-casting process. The structure is stable and not deformed, and it can work under harsh environment. The car paint has high grade and strong scratch resistance. It is still bright and new for many years.

4. When the cylinder is tested, the correction amount can be added automatically.

5. We have the ability to develop and design, manufacture and process our own machines, and provide replacement and maintenance upgrade services for the life of the machine;

Main use and the scope of application:

Cast and forged parts · Sample testing and acceptance testing

Planar and cylindrical workpieces ·Steel, non-ferrous metals

Automotive and aerospace industry ·Carbide, ceramic, stainless steel

Laboratory and workshop

2. Main technical parameter:

| Model | HRTS-150 |

| Intial test force(N) | 10kgf(98.07N) allowable error±2.0% |

| Total test force(N) | 60kgf(588N) 100kgf(980N) 150kgf(1471N) |

| Rockwell ruler | HRA、HRB、HRC、HRD、HRE、HRF、HRG、HRH、HRK HRL、HRM、HRP、HRR、HRS、HRV |

| Inspection standard | GB/T230.1、GB/T230.2national standard、JJG112certification procedure |

| accuracy | 0.1HR |

| Durating time(s) | 1-60 |

| Hardness reading | Tourch screen LCD display |

| Max height of the test piece(mm) | 170 |

| Indenter center to body distance(mm) | 165 |

| Hardness tester dimension(mm) | 550×220×730 |

| Power supply | 220V/50HZ |

| Tester weight(kg) | 85 |

| Hardness measuring range | HRA:20-88 HRB:20-100 HRC:20-70 HRD:40-77 HRE:70-94 HRF:60-100 HRG:30-94 HRH:80-100 HRK:40-100 HRL:100-120 HRM:85-110 HRR:114-125 HRS |

Jinan Focus Test Instrument Co., Ltd.

Jinan Focus Test Instrument Co., Ltd.

Jinan City, Shandong Province, China

Jinan City, Shandong Province, China